Independent testing results by USA audio expert Dave Askew

“I’m an audio professional who specializes in audio preservation and restoration, audio forensics and audio sciences. So to make me a believer in an audio product, I need to be extra discriminatory as to what’s happening on a microscopic level. My experience with Record Restore has left me quite astounded. It is undoubtedly one of the best products I’ve seen.

“Record Restore works by spreading it on the surface of the vinyl and peeling off the dried film. However, Record Restore does this with the utmost consideration to the physics of a vinyl record, and without leaving any chemical residue behind, or without causing any damage.

“Not only does it remove decades of particles (like nicotine from cigarette smoke and ‘diamond dust’ from the breakdown of the stylus), but it can remove even the original molding residue left from the manufacturing process.”

“In the end, I averaged the amount of noise over time, and took percentages of each recording. We ended up with an 11db increase in overall signal to noise ratio, which is around a 75% improvement in how it sounds to the logarithmic way that humans hear sound, and an 8db improvement to the peak noise floor, which is an improvement of over 50%.”

“I stand behind my measurements and say with confidence that Record Restore is a superior product that I would put my stamp of approval on, and entrust my entire vinyl collection to for years to come. While we can’t reverse the effects of aging, we can certainly control them, and Record Restore is the only way I’d recommend to any audiophile.”

Dave Askew

Here are audio files demonstrating the improvements after cleaning with Record Restore. Not only has noise from the contaminants been removed, more music has been revealed.

“In the after example, it is fascinating to note a few things you may not hear on first listen but can clearly see. There are no ‘pits’ or holes left over in the audio data where the ‘crud’ was removed. All of the musical information is retained, even in the upper harmonics. This means that there is no destruction of even the most sensitive parts of the vinyl.

“You can also see that the musical material looks brighter and stronger after cleaning. So the original musical material that you weren’t hearing before has resurfaced. This comes from the stylus being able to sit deeper in the groove and become more reactive to the grooves.

“You will also see at the beginning of the notes there is much more intensity vertically. This results in the restoration of audio transients and dynamic range. This will give you a deeper sense of accuracy and realism. In the cleaned version, you can clearly hear the hammer of the piano striking the note, which is difficult to hear in the dirty version.”

What was tested?

Five vinyl recordings were chosen with the intent to find recordings of different genres and dynamic content. Each recording saw different amounts of playtime, storage time, storage habits, and grime over the course of their history. The goal was to find consistent and measurable differences before and after Restore was applied.

How was it tested?

The first step was to digitize the chosen selections before and after Restore treatments were applied, and measure them with computer software. This was accomplished with modest consumer equipment available to anyone, in an average environment to prove that even the most humble equipment will see and hear the results.

How was it measured?

Each segment of audio that was tested, was aligned and measured at the exact precise times before and after cleaning. This would ensure the measurements that relied on timing were accurate. Not only did each recording need to be referenced to itself in terms of how well the product improved playback, but in a way that could be related to each other as well, since we were working with such a broad assortment of audio material.

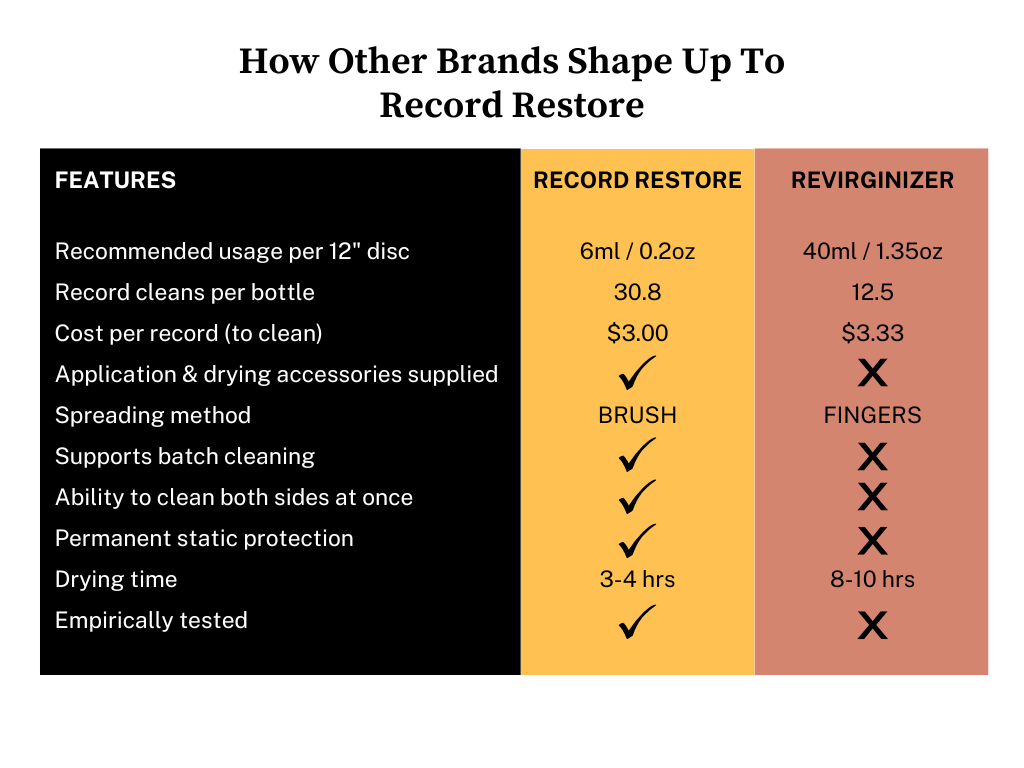

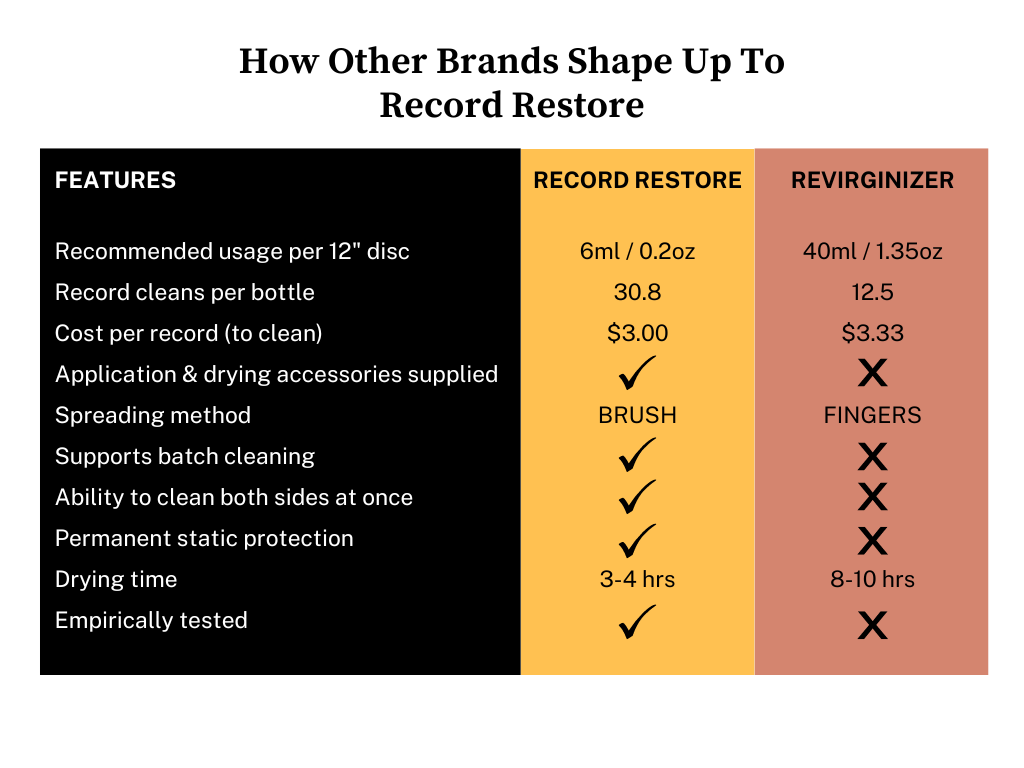

The chart on the first page is simply an overview of all of the tests that were performed, and it’s average percentage of improvement, with

the baseline measurements being taken from the original recording. It’s simply easier to visualize all of the data at a glance, without needing to do

all of the math.

The measurements for average db RMS, and the 4 different loudness measurements, are just a way of averaging loudness over a given period of time. So each show the same kind of data, with the exception that they are all weighted and averaged over different amounts of time and values.

The measurements for maximum digital peak, and minimum digital floor also factor in to the previous loudness measurements. We can think of the minimum digital floor as “hiss” or dirt, and the maximum digital peak as a “pop” or jump of the needle. There’s more to it than that, but it’s probably

the easiest way of explaining what these are. They are the immediate highest and lowest dynamic measurements in a recording. So being able to look at these afterwards is a great way of being able to see how Restore is pulling the grime out of a vinyl.

The difference between the highest and lowest values is called dynamic range. In all cases we’re looking to improve and increase dynamic range by pulling out the dirt and debris which create additional noise on top of the original recording. Conversely with the instantaneous and average

measurements we took, the lower the numbers after cleaning the better.

All things factored, these are simply just a narrow scope of what we can measure with modest equipment and a bit of math. So not only do the results show improvement on paper, but the results are stunning after using Record Restore.

Dave Askew

Media|DMA ©2020